US utilities must commit to digitization to cut operating costs by 30%

U.S. utility leaders must embrace digitization of nuclear work practices if the industry is to drive down costs and improve the efficiency of operations, leading digital experts told Nuclear Energy Insider.

Related Articles

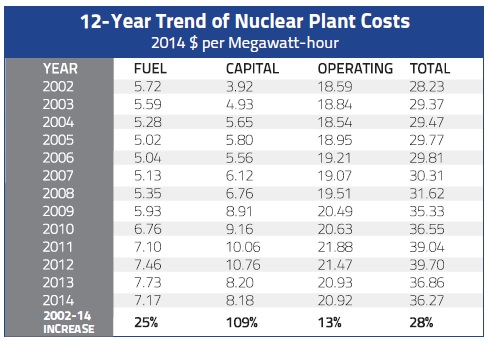

According to the Nuclear Energy Institute (NEI), generating costs of US reactors have risen by 28% over the last 12 years, which is impacting the competitiveness of nuclear power in a market being increasingly penetrated by natural gas and renewable energy.

The NEI aims to reverse this trend through its Delivering the Nuclear Promise (DNP) program, which was launched in December 2015 and will provide innovative solutions that can be introduced at plant level and help reduce industry-wide operating costs by 30% by January 2018.

The NEI estimates the DNP could deliver around $3 billion in savings by 2020. This figure is based on the average generation cost in 2012, which was around $40/MWh.

Source: Nuclear Energy Institute

Steven Kraft, Senior Technical Advisor at the NEI, told Nuclear Energy Insider that the aim is to deploy identified efficiency enhancements to the fleet by 2018, with cost savings emerging as individual plants implement the innovations.

“The 30% reduction in generating costs was selected by industry leaders to encourage innovative and transformational thinking. We don’t just want to trim the edges, but make significant changes that will advance safety, reliability and economic performance,” he said.

Although digitizing nuclear processes is already seen as one avenue to maximizing efficiency, Kraft said the industry had found it challenging to develop fully digital enhancements that would help optimize performance due in part to an outdated regulatory infrastructure.

Waco Bankston, Chief Information Officer and Director of Cyber Security at STP Nuclear Operating Company, told Nuclear Energy Insider that the DNP goals are achievable, but added there needed to be a shift in culture across the industry to accept digitization, which has a pivotal role in optimizing and cutting the costs of operations.

“Nuclear professionals and human beings in general tend to be averse to change and want to hold onto the status quo and although we don’t want to invent completely new practices, we can change things to make them more efficient,” he said.

Live streaming

STP is already realizing the benefits to workers and budgets from a program to digitize work procedures and processes that enhance safety, streamline work flows, eliminate duplication of effort and save time and costs.

Health physics safety personnel are exposed to picking up radiation dosage while monitoring the decontamination of equipment, but installing a video surveillance management system to check decontamination and containment areas had proved effective in improving safety, Bankston said.

Introducing a camera to remotely capture readings from measuring instruments had reduced the time employees needed to spend in radioactive areas and the dose they might receive, he said.

Bankston also described an added benefit of using video surveillance to cut costs associated with consulting contractors on arising problems. Prior to this system, a crew would be deployed to a critical outage incident and shoot footage that would be burned to DVD and sent by mail to the contractors.

The cost of the outage can amount to millions of dollars per day, but a system that allows live streaming from the incident location to the contractors enables issues to be evaluated in real time and solved more rapidly. Less money and fewer hours are spent correcting the problem, resulting in significant savings.

Digitizing paperwork

Trials replacing paper-based processes with electronic work packages (e-WP) are showing significant improvement to employee productivity. Maintenance workers are issued with a mobile device that enables a work package to be planned, executed and closed out solely in a digital format.

Scott Madden Inc, a management consulting firm, piloted smart-branched e-WPs with nuclear operators. Partner Sean Lawrie told Nuclear Energy Insider that the software program eliminates redundant steps when working through a work package, which results in leaner and more targeted work and data flows.

Tangible cost benefits are visible almost immediately through the removal of printed paper and packaging associated with the work package. In addition, a reduced number of planning hours saves labor costs.

Lawrie said the DNP initiative was gaining traction and the DNP goal of achieving a 30% reduction in costs is possible, but utility leaders will need to be prepared to accept significantly streamlined processes.

“Less of a cultural shift to accept digitization is needed in the workers, as many craft employees are demanding better tools and want e-WPs. However, utility leadership will need to commit an investment to achieve annual savings in labour and non-labour costs,” he said.

“The true value of smart-branched e-WPs is not just from the execution of the packages, but the additional digital data and improved accuracy of data that is collected during the execution of the work packages.”

By Karen Thomas